Our aluminium solutions for trains also provide you with benefits that you may not have considered. We lower the footprint of our components by manufacturing the solutions you need, including fabrication services, from plants near you. We can point to successful partnerships through close technical collaboration and assembly of train modules. And we are reliable, transparent through our high-quality standards.

This eliminates risks for your company.

Where can you find our extruded solutions in modern trains? Mostly in structural parts, interior and exterior:

- Body sides (side walls)

- Roof and floor panels

- Cant rails, which connect the floor of the train to the side walls

Technical expertise in development and production

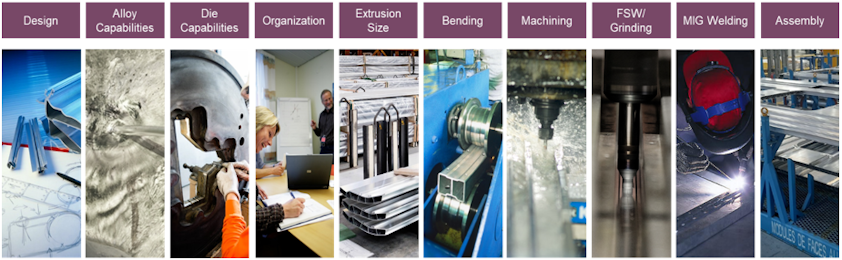

Our solutions for trains can save you costs when they are made smartly, as when our technical specialists are brought into the development phase at an early stage. Various other added-value activities are shown below.

As an example, when interior and exterior train elements need to be bigger, welding is often involved.

TIG / MIG welding

Using the TIG or MIG process to join 6000-series aluminium alloys is a smart option. It is also possible with aluminium extrusions to integrate functions that facilitate welding.

Using the FSW process provides you with a flush and homogeneous weld that is obtained by mixing the material with a rotating tool. Its advantages include reduced deformation and excellent thermal conductivity.

Kitting and assembling

By supplying kits, we can lessen your manual work and material handling. This reduces your costs.

The kit of your train body can be done according to all your specifications, such as specific wedging, protection by filming, integration of bags of screws, and the installation of stickers.

Because we want to see your continued success in the train industry, we can support you with:

- Personal assistance

- Design support and technical engineering and feasibility studies

- An experienced project team focused on proactive project and logistical management

- A European network that offers options for partnering and subcontracting

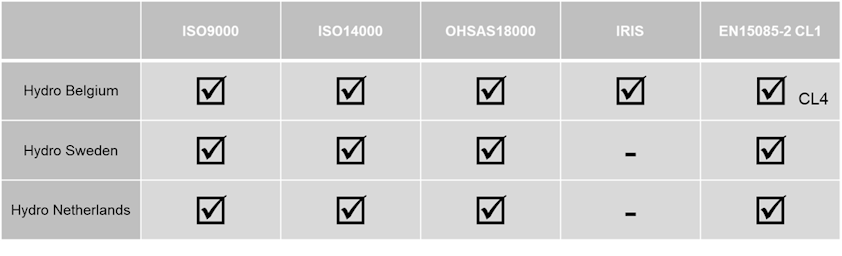

- A fully certified supply chain

Updated: November 10, 2022