PLEASE NOTE THAT THE CUSTOMER’S PURCHASE ORDER SUBMITTED TO EXTRUSION NORTH AMERICA (ENA) MAY ONLY REFERENCE THOSE SPECIFICATIONS DESIGNATED BELOW WITH AN ASTERISK (*). IN ADDITION, ENA WILL ONLY ACCEPT THE LATEST REVISION OF THE APPLICABLE SPECIFICATION. PROCESS VARIABILITY IS DISCUSSED IN MORE DETAIL BELOW. FURTHER EXCEPTIONS TO PROCESS REQUIREMENTS MAY OCCUR THROUGH AGREEMENT WITH THE CUSTOMER.

ENA’S INTERPRETATION OF THESE TECHNICAL SPECIFICATIONS MAY NOT BE APPROPRIATE FOR USE BY OTHERS AND IS SUBJECT TO CHANGE WITHOUT NOTICE. CUSTOMERS SHOULD, THEREFORE, PERIODICALLY VISIT THIS WEBSITE.

GENERAL POLICY AGAINST FLIGHT CRITICAL OR STRUCTURAL AEROSPACE APPLICATIONS:

ENA does not expect or intend any of its extrusions to be used or incorporated into flight critical (See Footnote 1) or structural aerospace applications.

SPECIAL NOTE ON CHEMISTRY: Depending on the ENA facility supplying the extrusions, chemistry is reported either (1) as actual chemistry or (2) as Table 1 chemistry ranges. Actual chemistry is available upon request. Exceptions to the required reporting of actual chemistry within the ASME specifications may occur through agreement with the customer.

CUSTOMER ORDERS WITHOUT SPECIFICATIONS NOTED: When a customer does not identify a standard specification for their order, ENA will default to the specification applicable to the product type being ordered (e.g., ASTM B221, ASTM B241/B241M, etc). Further, the mechanical property testing requirement is automatically waived and, as such, a Certified Test Report will not be provided for that order.

Additional Helpful Information

I. AMERICAN STANDARDS – ASTM and ASME:

*ASTM B221-21 and B221M-21 & B241/B241M-22: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wires, Profiles, and Tubes (B221/B221M) and Seamless Pipe and Extruded Tube (B241/B241M).

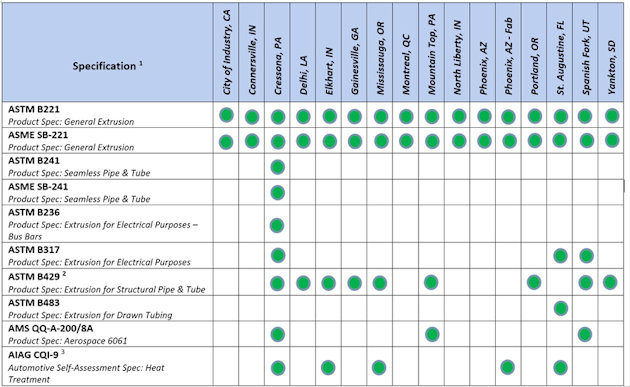

These baseline specifications for aluminum extrusion product requirements set forth mechanical properties and chemical composition limits. Acceptable ranges within such limits comprise the basis for ENA's certification within the tables below.

B221-21 & B221M-21

Table 1 Chemical Composition Limits

Table 2 Mechanical Property Limits

B241/B241M-22

Table 1 Tensile Property Limits for Pipe, [Inch Pound Units]

Table 2 Tensile Property Limits for Pipe, [SI Units]

Table 3 Tensile Property Limits for Extruded Tube, [Inch Pound Units]

Table 4 Tensile Property Limits for Extruded Tube, [SI Units]

Table 5 Composition Limits

NOTE: For orders requesting certification to both B221 and B241, please note that the limits in the tables for mechanical property and tensile property, respectively, are different for 6105-T5 and 6082-T6. Accordingly, the customer will need to select either B221 or B241, but not both, when ordering 6105-T5 and 6082-T6. If customer does not select either B221 or B241, then the order will default to the mechanical property limits for 6105-T5 and 6082-T6 set forth in B221.

*ASME SB-221-21: Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

This specification is identical to ASTM B221 except that certification and test reports, as described therein, are mandatory (See Section 22). However, ENA only provides a certified test report for mechanical properties. Actual chemistry results are not reported unless agreed upon between ENA and the customer. Other testing requirements are not reported on ENA’s Certified Test Report as they are not applicable. Although there is a metric version of ASTM B221, there are no metric versions for this specification. Acceptable ranges comprise the basis for ENA’s certification within the tables below.

Table 1 Chemical Composition Limits

Table 2 Mechanical Property Limits

*ASME SB-241/SB-241M-17: Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube.

This specification is identical to ASTM B241/B241M except that certification and test reports, as described therein, are mandatory (See Section 21). However, ENA only provides a certified test report for mechanical properties. Actual chemistry results are not reported unless agreed upon between ENA and the customer. Other testing requirements are not reported on ENA’s Certified Test Report as they are not applicable. Acceptable ranges within the tables below comprise the basis for ENA’s certification.

Table 1 Tensile Property Limits for Pipe, [Inch Pound Units]

Table 2 Tensile Property Limits for Pipe, [SI Units]

Table 3 Tensile Property Limits for Extruded Tube, [Inch Pound Units]

Table 4 Tensile Property Limits for Extruded Tube, [SI Units]

Table 5 Composition Limits

*ASTM B236-15 and B236M-15: Standard Specification for Aluminum Bars for Electrical Purposes - Bus Bars.

This specification sets forth the electrical properties required for the production of extrusions used in electrical applications. It is only applicable to the 1350 alloy in certain H tempers. ENA sets the bending frequency, method, and specimen dimensions for testing material ductility used in electrical applications per ASTM E290. Electrical resistivity and conductivity are tested in accordance with ASTM B193, ASTM E1004 (via eddy-current method), or as otherwise agreed with the customer. Electrical resistivity testing is only conducted when needed to assess the adequacy of the extrusion in the case of a measurement value dispute regarding conductivity. Acceptable ranges within the tables below comprise the basis for ENA's certification.

Table 1 Tensile Property Limits

Table 2 Chemical Composition Limits

Table 3 Edgewise Bend Radius

Section 11 Electrical Properties

*ASTM B308/B308M-20: Standard Specification for Aluminum-Alloy 6061-T6 Standard Structural Profiles.

This specification covers extruded 6061-T6 aluminum alloy structural profiles such as I-beams, H-beams, channels, angles, tees, and zees. This specification generally aligns with the 6061-T6 requirements of ASTM B221 except B308/308M requires hardness testing. Hardness testing will generally not be performed. It will only be performed upon agreement between ENA and the customer including agreement on a mutually defined sampling plan. In such event, a notation will be included on the Certified Test Report indicating hardness testing has been performed. See also Section 11 (Quality Assurance Screening of Extrusion Press Heat-Treated Shapes). Acceptable ranges within the tables below comprise the basis for ENA's certification.

Table 1 Chemical Composition Limits

Table 2 Tensile Property Limits

*ASTM B317/B317M-15: Standard Specification for Aluminum-Alloy Extruded Bar, Rod, Tube, Structural Profiles, and Profiles for Electrical Purposes (Bus Conductors).

This specification sets forth the electrical properties required for the production of extrusions used in electrical applications. It is only applicable to the 6101 alloy. ENA sets the bending frequency, method, and specimen dimensions for testing material ductility used in electrical applications per ASTM E290. Electrical conductivity is tested in accordance with ASTM B193 or as otherwise agreed with the customer. Electrical resistivity testing is conducted in accordance with ASTM E1004 (via eddy-current method), but only when needed to assess the adequacy of the extrusion in the case of a measurement value dispute regarding conductivity. Acceptable ranges within the tables below comprise the basis for ENA's certification.

Table 1 Chemical Composition Limits

Table 2 Tensile Property Limits

Table 3 Flatwise Bend Radii

Table 4 Resistivity & Conductivity Limits

*ASTM B429/B429M-20: Standard Specification for Aluminum-Alloy Extruded Structural Pipe and Tube.

This specification sets forth mechanical properties and chemical composition limits for porthole die-extruded structural pipe and tube. Acceptable ranges within such limits comprise the basis of ENA’s certification. Pipe and tube dimensional and tolerancing requirements are agreed upon with the customer on a case by case basis and requirements are noted on the customer drawing. Acceptable ranges within the tables below comprise the basis for ENA’s certification.

Table 1 Chemical Composition Limits

Table 2 Tensile Property Limits

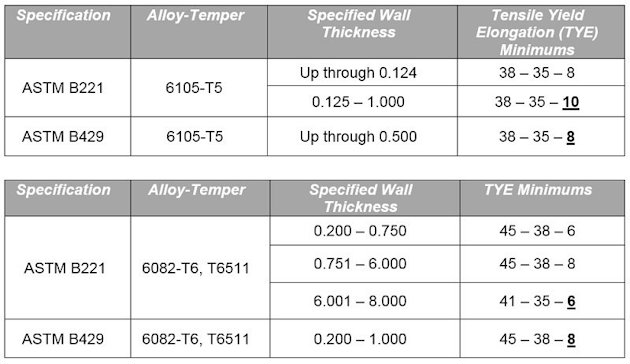

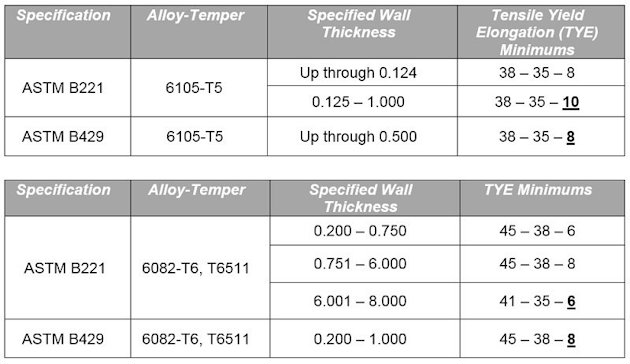

NOTE: For orders requesting certification to both B221 and B429, please note that the Specified Wall Thickness in Table 2 in certain alloy and temper combinations contains different ranges of mechanical property limits for B221 and B429 for the higher wall thickness values. Examples of such differences are set forth in the table below. As a result of these differences, the customer will need to select either B221 or B429, but not both, when ordering certain alloy and temper combinations. If customer does not select either B221 or B429, then the order will default to the Mechanical Property Limits set forth in B221.

EXAMPLE:

*ASTM B483/B483M-21: Standard Specification for Aluminum and Aluminum-Alloy Drawn Tube and Drawn Pipe for General Purpose Applications.

This specification sets forth mechanical properties and chemical composition limits for drawn tube and pipe. Acceptable ranges within such limits comprise the basis of ENA’s certification. Extrusion press quench practices are allowed in lieu of furnace solution heat treatment by agreement with the customer and alignment with AMS 2772 shall not apply. Process variability is discussed in more detail below. Acceptable ranges within the tables below comprise the basis for ENA’s certification.

Table 1 Tensile Property Limits, Tube

Table 2 Tensile Property Limits, Drawn Pipe

Table 3 Chemical Composition Limits

ASTM B557-23 and B557M-23: Standard Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products.

This testing specification sets forth the parameters and methods for tension testing of aluminum alloys. ENA meets the material requirements of this specification with some exceptions including, but not limited to, variability in specimen location cut from the profile sample, and reporting of elongation method on the Certified Test Report. Elongation method used is available upon request.

ASTM B594-19e1: Standard Practice for Ultrasonic Inspection of Aluminum-Alloy Wrought Products.

This testing specification sets forth the parameters and methods for detecting internal discontinuities (e.g., inclusion) in the product using immersion or contact ultrasonic techniques to define applicable quality levels in aluminum-alloy wrought products. Testing is performed by a certified third party. This testing is only performed when agreed upon between ENA and the customer. When requested, a notation will be included on the Certified Test Report generally consistent with the following statement:

Material has been ultrasonically inspected post-extrusion in accordance with ASTM B594 (latest revision).

ASTM B660-21: Standard Practice for Packaging / Packing of Aluminum and Magnesium Products.

This process standard practice describes methods of packaging and packing of aluminum products in preparation for storage or shipment, both foreign and domestic. ENA develops custom packaging requirements directly with the customer and develops internal standard practices in order to help comply with those requirements. There is no metric version of this practice.

ASTM B666/B666M-20: Standard Practice for Identification Marking of Aluminum and Magnesium Products.

This process standard practice establishes the physical item marking requirements for identification purposes for aluminum products. The standard practice does not include package marking for shipment and inspection acceptance. ENA develops customer-specific marking requirements with the customer and develops internal standard practices in order to help comply with those requirements. If ENA and the customer agree to follow the marking requirements set forth in this specification, a notation will be included on the Certified Test Report generally consistent with the following statement:

Marking has been performed in accordance with ASTM B666 (latest revision).

ASTM B807/807M-20:Standard Specification for Extrusion Press Solution Heat Treatment for Aluminum Alloys.

This specification sets forth process control requirements for the press extrusion quench process for select alloy/temper combinations. ENA press quenches extrusions and utilizes a programmable logic controller (PLC) driven “run to recipe” system for process control, including temperature controls throughout the extrusion process. Quench is achieved (via air or water) and monitored by infrared camera at some plants. Quenching the extrusion at the press, coupled with subsequent precipitation strengthening processes (e.g., aging), can be used as a substitute for furnace solution heat treatment as a viable means of achieving mechanical properties.

The “run to recipe” system is designed to help provide a recommended setup for the extrusion process to achieve a customer’s mechanical property requirements up through and including the press exit temperature (but does not include the quench process). While statistical review and capability verification of mechanical properties is not currently part of process validation, mechanical testing of material is used to verify mechanical properties.

ASTM B918/B918M-20a: Standard Practice for Heat Treatment of Wrought Aluminum Alloys.

This process specification sets forth general post-extrusion quench aging processes. ENA conducts Temperature Uniformity Surveys (TUS) with variability in frequency and methodology. In certain locations, System Accuracy Tests (SAT) are performed with variation in frequency and pyrometry as compared to those outlined in B918.

ENA develops its own heat treating (aging) cycles based upon analysis and empirical mechanical property results. Results of quench and heat treatment are validated through mechanical property testing.

*AMS QQ-A-200/8A: Aerospace Standard for Aluminum Alloy 6061 Bar, Rod, Shapes, Tube, and Wire.

This aerospace process specification sets forth the general requirements for 6061 alloy press- quenched material. Please note, however, there are a limited number of ENA plants which produce extrusions to this specification.

AMS 2750G-22: Aerospace Furnace Pyrometry Requirements.

This aerospace process specification sets forth specific heat treatment pyrometry requirements for furnace equipment. Practices for heat treating technical requirements, pyrometry, quench control, and statistical process verification are administered through ENA-developed internal methods. While this process specification is included in other product specifications (e.g., ASTM B221), this process specification is only used in reference to aging requirements for AMS QQ-A-200/8A. Material is validated as meeting customer property requirements through use of hardness checks and mechanical property testing.

AMS 2772H-22: Aerospace Heat Treatment of Aluminum Alloy Raw Materials.

This aerospace process specification sets forth general requirements for aluminum alloys produced requiring solution heat treatment. The specification is generally only used for hard alloy extrusions. Practices for heat treating technical requirements, pyrometry, quench control, and statistical process verification are administered through ENA-developed internal methods. While this process specification is included in other product specifications (e.g., ASTM B221), this process specification is only used in reference to aging requirements for AMS QQ-A-200/8A. Material is validated as meeting customer property requirements through use of hardness checks and mechanical property testing.

AMS STD-2154-E (2021): Process for Ultrasonic Inspection of Wrought Metals.

The process specification sets forth uniform methods for the ultrasonic inspection of wrought metals and wrought metal products. ENA defaults to ASTM B594 (latest revision) as the standard specification for ultrasonic inspection. However, if ENA and the customer agree to use this specification for ultrasonic inspection, then a certified third party will perform such inspection. In addition, a notation will be included on the Certified Test Report generally consistent with the following statement:

Material has been ultrasonically inspected post-extrusion in accordance with AMS STD-2154 (latest revision).

MIL-DTL-25995E with Amendment 1-20: Detail Specification – Pipe, Aluminum Alloy, Drawn or Extruded.

This Department of Defense specification encompasses a number of applicable ASTM specifications. Depending on the extrusion ordered, the customer should instead refer to the applicable ASTM specification required and not include references to this specification on its purchase order.

Applicable replacement specifications include for Type A extrusions: ASTM B221 (General Extrusion), ASTM B429/B429M (Structural), ASTM B483 (Drawn Tube and Pipe); and for Type B extrusions: ASTM B241/B241M (Seamless Pipe and Tube).

Temper Alignment of T6H and T6511H: ENA offers 'H' temper for special applications of 6061 requiring improved machinability (through stress relief by stretching) and higher minimum mechanical properties than standard T6 or T6511. 'H' temper is available for rod, bar, and certain profiles with a principal thickness (i.e., test sample location) of 0.500 inches or greater. ENA provides this 'H' temper upon customer request. When requested, a non-certified notation (See Footnote 2) will be included on the Certified Test Report generally consistent with one of the following statements:

For alloys 6061, 6262, 6082 in the -T6511 Temper: Extrusions produced to -T6511 temper also meet -T6 temper requirements.

For Acc-U-Rod® and Acc-U-Bar® Products: Extrusions produced to -T6511H temper also meet -T6H, T6511 and -T6 temper requirements.

II. INTERNATIONAL STANDARDS – European, German, & Japanese:

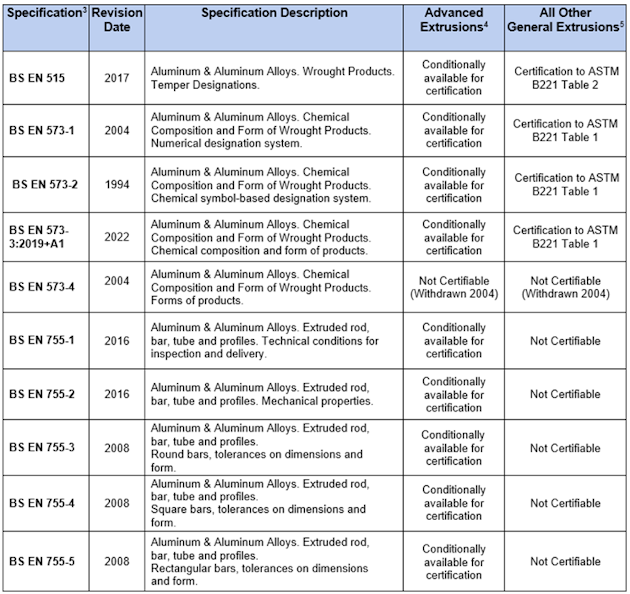

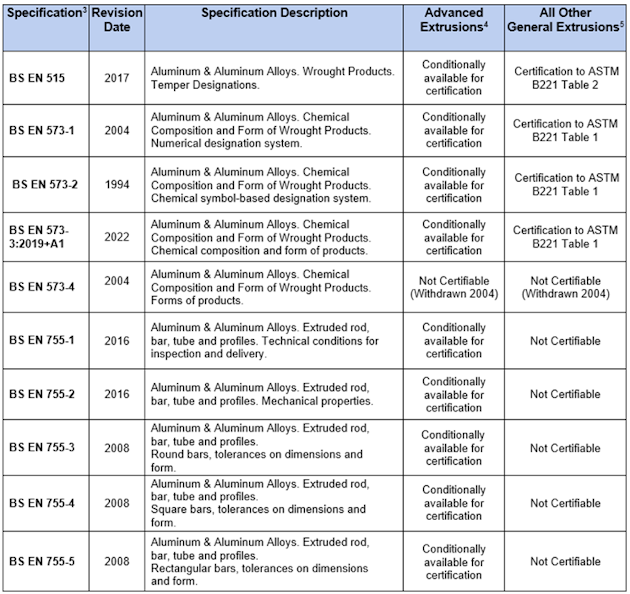

The European Standards (EN) are documents that have been ratified by one of the three European Standards Organizations (European Committee for Standardization (CEN), European Committee for Electrotechnical Standardization (CENELEC), or European Telecommunication Standards Institute (ETSI)). 'BS EN' is a national standard of the EN translated and interpreted into the English language for use in the United Kingdom. For certain automotive and aerospace customers or other specialized original equipment manufacturers (OEM), ENA will certify to BS EN for extrusions as indicated below or as otherwise agreed upon in conjunction with an Advanced Product Quality Planning (APQP) or Production Part Approval Process (PPAP) (and such extrusions are referred to herein as 'Advanced Extrusions').

BS EN 515: Aluminum & Aluminum Alloys. Wrought Products – Temper Designations.

Refer to ASTM B221 or B221M Table 2 Mechanical Property Limits for the various ASTM-designated alloy and temper combinations. While naming conventions in this specification generally align to ASTM B221 or B221M, any temper designation in this specification that is not found in Table 2 should be mutually agreed upon between ENA and the Advanced Extrusions customer. If such agreement is reached, a notation on the Certified Test Report can be provided upon request generally consistent with the following statement:

Material produced to mutually agreed upon temper designations as defined by BS EN 515.

BS EN 573: Aluminum & Aluminum Alloys. Chemical Composition and Form of Wrought Products.

This is a multi-part document. See the table above for the latest revision date.

- BS EN 573-1: This section characterizes the general method of naming alloy series based on the primary alloying element in each material. Actual chemistries to which ENA produces material should reference ASTM B221 or B221M, Table 1 Chemical Composition Limits.

- BS EN 573-2: This section provides a variant on the naming convention (i.e., EN AW-6061 [Al Mg1SiCu]), which incorporates general information about alloying. In this case, 'A' designates 'aluminum' and 'W' indicates a 'wrought product'. ENA does not use this naming convention. ENA will not certify to or reference BS EN 573-2. Refer to ASTM B221 or B221M Table 1 (Chemical Composition Limits) for the convention used by ENA.

- BS EN 573-3: This section provides element-for-element composition requirements for each EN-AW-XXXX alloy designation. Given some deviation to the ASTM chemistry requirements, ENA will default to chemical composition listed in the relevant ASTM table. Refer and order to ASTM B221 or B221M Table 1 for the chemistry to which the material is produced. If it is confirmed that the EN-AW-XXXX alloy chemistry is identical to the ASTM B221 XXXX chemistry, then a notation on the Certified Test Report can be provided upon request generally consistent with the following statement:

Material produced aligns with chemistry of applicable chemical composition table in ASTM and BS EN 573-3.

- BS EN 573-4: Withdrawn in 2004. Not certifiable.

BS EN 755: Aluminum & Aluminum Alloys. Extruded Rod, Bar, Tube and Profiles.

This is a multi-part document. See the table above for the latest revision date.

- BS EN 755-1: This section specifies the technical conditions for inspection, delivery, and mechanical property testing methods. While the specification itself contains information similar to the general extrusion specification ASTM B221 and the tension testing specification ASTM B557, the requirements are not fully in alignment with ASTM requirements. ENA does not produce general extrusions to this specification.

- BS EN 755-2: This section specifies mechanical properties according to alloy designations (BS EN 573-3) and tempers (BS EN 515). While the specification itself contains information similar to the general extrusion specification ASTM B221, the requirements are not fully in alignment with ASTM designations. ENA does not produce general extrusions to this specification.

- BS EN 755-3 through 9: These sections specify the tolerances on dimensions and form for aluminum alloy extrusions of various types and ranges of cross sectional thickness. ENA develops customer dimensional and tolerance requirements through review and mutual sign off on an engineering drawing of the profile. These parameters are not recognized on Certified Test Reports.

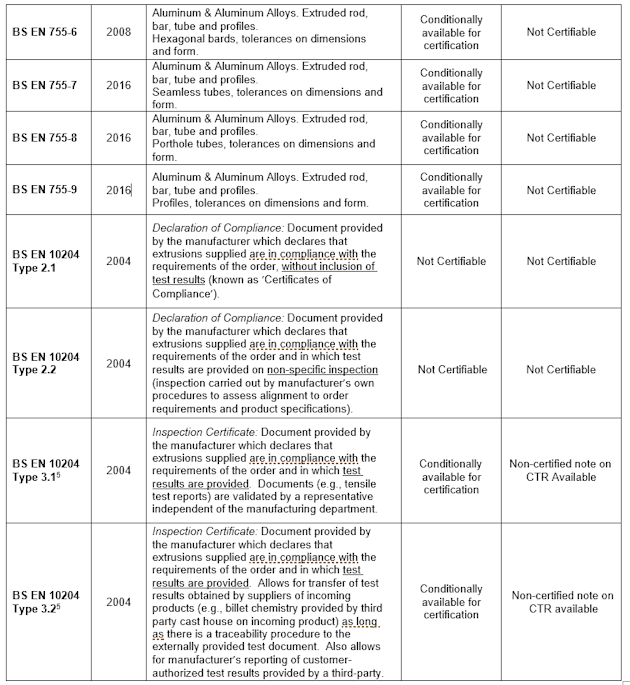

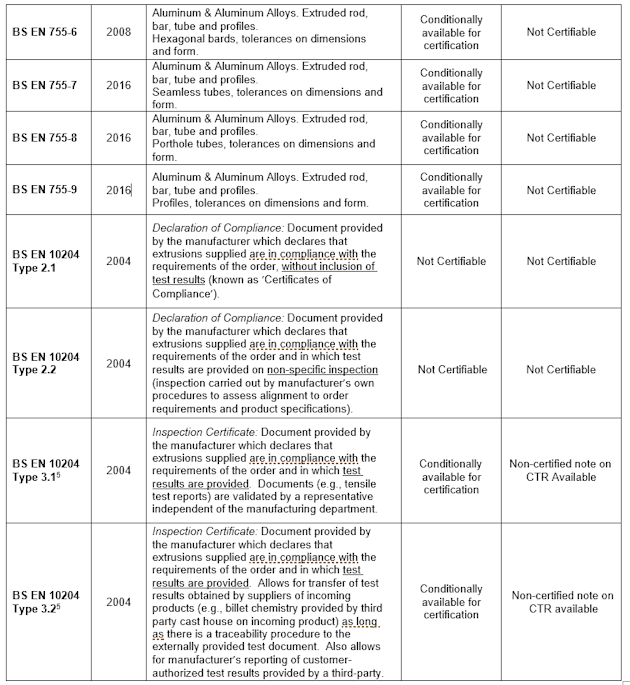

BS EN 10204:2004: Metallic Products – Types of Inspection Documents.

ENA does not provide Certificates of Compliance (unless specifically agreed upon with the customer in advance of the order) and shall not provide certification to a Type 2.1 document. ENA does not test products internally with laboratories external to the manufacturing department and so cannot provide Types 2.1, 2.2, 3.1, and 3.2 documents as written. For 3.1 and 3.2 only, a notation on the Certified Test Report can be provided upon request generally consistent with the following statement:

Material produced to BS EN 10204 (Types 3.1 and 3.2) only with provision of mechanical and chemical test reports at the time of shipment. Mechanical Property Testing is performed by the quality department which reports to the manufacturing organization at the producing site. Chemical Composition testing is performed by the billet producer.

Germany: The German Institute for Standardization (DIN or Deutsches Institut fűr Normung) develops standards for rationalization, quality assurance, and other industrial areas. ENA will certify to DIN standards only for certain custom automotive extrusions in conjunction with an APQP/PPAP process.

Japan: The Japanese Industrial Standards (JIS or 日本工業規格 Nihon Kōgyō Kikaku) specifies the standards used for industrial activities in Japan. The standardization process is coordinated by the Japanese Industrial Standards Committee (JISC) and published through the Japanese Standards Association (JSA). ENA will certify to JIS standards only for certain custom automotive extrusions in conjunction with an APQP/PPAP process.

III. Cancelled or Superseded Specifications:

Please note that ENA will not accept orders to cancelled or superseded specifications:

ASTM B345/B345M-11: Cancelled (2017). Replaced by *ASTM B241/241M-16

Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube for Gas and Oil Transmission and Distribution Piping Systems

AMS QQ-A-200/1: Cancelled (2007). Replaced by *ASTM B221-21, *ASTM B221M-21, *ASTM B241/B241M-16

Aluminum Alloy 3003, Bar, Rod, Shapes, Tube, and Wire, Extruded

AMS QQ-A-200/9: Cancelled (2007). Replaced by *ASTM B221-21, *ASTM B221M-21, *ASTM B241/B241M-16

Aluminum Alloy 6063, Bar, Rod, Shapes, Tube, and Wire, Extruded

AMS QQ-A-200/10: Cancelled (2007). Replaced by *ASTM B221-21, *ASTM B221M-21, *ASTM B241/B241M-16

Aluminum Alloy 6066, Bar, Rod, Shapes, Tube, and Wire, Extruded

AMS QQ-A-200/16: Cancelled (2007). Replaced by *ASTM B221-21, *ASTM B221M-21

Aluminum Alloy, Structural Shapes, Extruded 6061

AMS QQ-A-200/17: Cancelled (2007). Replaced by *ASTM B221-21, *ASTM B221M-21, *ASTM B241/B241M-16

Aluminum Alloy 6162, Bar, Rod, Shapes, Tube, and Wire, Extruded

BS EN 573-2:2004: Withdrawn (2004)

Aluminum & Aluminum Alloys. Chemical Composition and Form of Wrought Products. Forms of products.

Footnote 1: Extrusions are flight critical if used in any aircraft part, assembly, or installation containing a critical characteristic whose failure, malfunction, or absence could cause a catastrophic failure resulting in engine shut-down or loss or serious damage to the aircraft resulting in an unsafe condition. Aircraft includes unmanned aircraft, satellites, missiles, and rockets. Examples of flight critical applications for extrusions include, but are not limited to, structural pieces, fuel systems and mountings, stage separation components, and engine and propulsion products.

Footnote 2: Notations included on the Certified Test Report are provided as an accommodation to the customer and shall not be construed to be a certifiable statement.

Footnote 3: Please note the ASTM standards do not fully align with the EN or BS EN specifications. When transitioning an order from EN or BS EN to ASTM, please be sure to discuss with an ENA technical representative to review the specifications and understand the differences.

Footnote 4: Advanced Extrusions, as defined above, includes extrusions for automotive or aerospace use and any extrusion where the PPAP or APQP method of evaluating and verifying conformance to customer requirements is used in advance of production. EN or BS EN specifications can be certified by ENA when customer-specific processes aligned to those above-referenced BS EN or EN specifications, as applicable, are agreed upon between customer and ENA and implemented with respect to such Advanced Extrusions.

Footnote 5: EN or BS EN specifications are not available for certification on general extrusions or any other extrusion not included within the definition of Advanced Extrusions above. For certain EN or BS EN specifications, a non-certified notation may be included on the Certified Test Report.

Footnote 6: Please note that the revision register will only be used to identify material changes to these interpretations.

Click Here to Download a PDF Copy of this Document Page

Rev. 0, Initial Document Release, Adams, 09/12/2018

Rev. 1, Revisions and Additions, Adams, 11/14/2018

Rev 2, Revisions and Additions, Adams, 01/12/2019

Rev 3, Revisions and Additions, Adams, 3/12/2019

Rev 4, Revisions and Additions, Moore, 8/01/2022

Rev 5, Revisions and Additions, Moore, 7/21/2023