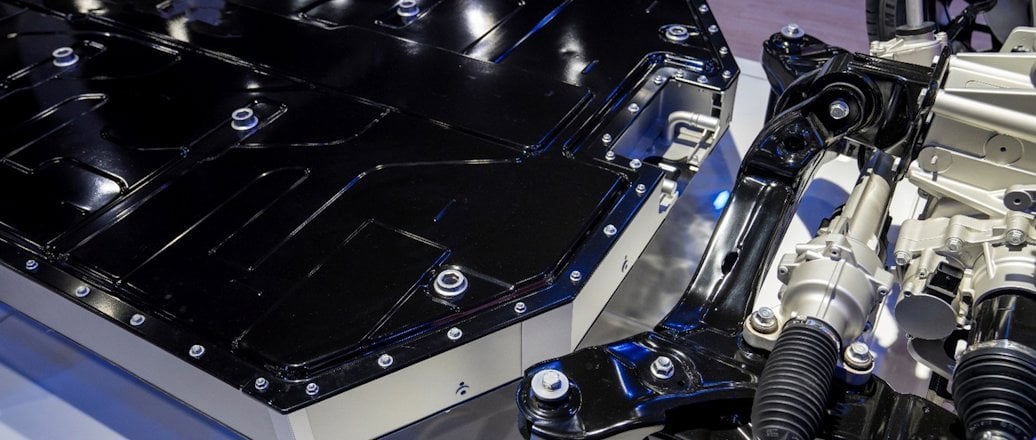

Aluminium for battery products

As the demand for electric vehicles continues to rise, Hydro has committed to support the growing market through investments, technology developments and product understanding.

With our network of extrusion presses, we can manufacture extruded profiles in a variety of automotive grade alloys benefiting from weight-to-strength ratio, corrosion resistance and thermal management. Through an extensive catalogue of fabrication capabilities, including high accuracy CNC machining and MiG / TiG welding, we can develop your long-length extrusions into functional automotive battery components.

Product examples

Our portfolio of components includes enclosure frames, aluminium battery cables, cooling systems, thermal management systems, engine housings, battery trays and structural body components suitable for fully electric vehicles as well as hybrid engine vehicles.

Utilizing our integrated supply system, we control manufacturing processes from billet supply to extrusion, machining and fabrication, surface treatment and assembly – with full traceability.

Lightweight, high-strength aluminium

With EV batteries requiring many components and large amounts of material, weight saving can be a priority for automotive designers and car makers. Our offering of lightweight, high-strength aluminium can support you in your search for weight savings.

- It’s light: Improve fuel efficiency and reduce CO2 emissions through optimized design and substantial weight reductions.

- It’s safer: Industry-specific alloys built from research for improved strength and enhanced energy absorbption for crash performance and roll protection.

- It may have been used before: Our range of low-carbon and recycled-content aluminium alloys can help you improve the impact of your design in terms of carbon footprint and sustainability. With no compromise in quality.

- Our Automotive DNA: Hydro has produced aluminium components for automotive application for over 50 years. Our experience and expertise has driven our ever-growing ‘Automotive DNA’ for understanding customer needs, providing high-quality parts consistently and allowing for full traceability.

- Research & Development: We have a dedicated team working continuously in improving our offering for automotive customers. This includes alloy development, quality control and manufacturing processes.

- Project support: Whether you have a fully functional design or just an idea, our technical team can support you through material choice and design modifications all the way through to testing and logistics.

Aggiornato: 19 luglio 2023