From oil & gas to battery materials: Closing the loop on a bold career

Hydro’s history over the past few decades has been nothing short of exploring various opportunities. Ellen Stange’s 40 year career in Hydro is a story of breaking ground in various projects which have shaped both the company and the industry.

“Varied, developmental and challenging.” These are the three words Ellen uses to describe her career in Hydro. A career which is now nearing the end, with many groundbreaking projects to look back at. But for Ellen, the word fun is a word which encompasses everything. It has been fun all the time because it has been so varied.

What is most fun is being part of a project, to succeed with what you planned for. Being part of a project is being part of something bigger, of a greater purpose.

Ellen’s career in Hydro started 40 years ago, working with technology projects in the oil and gas division. At the time, oil and gas projects were booming. Hydro had joined the race for oil exploration in the North Sea some years earlier, together with mostly international companies. When the first oil discovery was made on the Norwegian continental shelf, Hydro was the only Norwegian partner.

Hydro and Norway as a nation faced a new reality. Oil revenues and technology development laid the foundation for unparalleled growth, including the development of the modern welfare state in Norway.

Among other projects, Ellen worked on technology development of the Troll-Oseberg Gas Injection project, which supplied gas to Oseberg from the nearby Troll field. The NOK 3 billion project was operated by Hydro and started production in 1991.

“I applied for a job in Hydro because I wanted to be part of where the decisions were taken. We were so many young people exploring new things that had never been done before. It was very varied with a lot of challenges for someone in the beginning of their career. Hydro was a technology company who wanted to have control of the technology themselves. It was really exciting,” says Ellen.

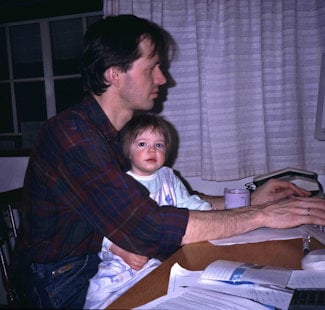

Neighbors did not greet the family

When Ellen was working on the Oseberg project in the 1990s, she and her family relocated to Haugesund. The traditional Norwegian family roles of the time were turned upside down. Not only was Ellen’s husband probably one of the first people in Norway to pioneer what is today commonly known as the “home office.” He was working part-time for Hydro, while also being a stay at home dad for their young children. This was quite groundbreaking for the time.

“The neighborhood thought it was strange and completely unheard of. My husband only worked 40 percent, was taking care of the kids and had the majority of responsibilities at home, while I was working on site. In many people’s eyes, this was a family which was unheard of to talk to. Some of the neighbors would not say hello to us,” says Ellen while she laughs and shakes her head.

Ellen explains that this attitude did not really impact the family much. They were busy enough with themselves, their family and important industrial projects they were working on.

The development of the Oseberg field is one of the most significant milestones in Norway’s independent oil and gas history.

“Working in the oil and gas division of Hydro was a lot of action, fun and filled with challenges. I was a process engineer in the start of my career, and we did a lot of groundbreaking technology development within process technologies for oil and gas projects.”

The North Sea has been Hydro’s home ground for nearly 40 years. Hydro, and Ellen, had now made their mark on technology development on the Norwegian continental shelf.

A big transition from oil to aluminium

In the early 2000s, Ellen’s unique competence from structuring projects was needed and her career took new turns. No longer in oil, but in aluminium. On the back of decades in the oil and gas industry, Hydro was looking to become a leading market player in the aluminium industry.

After heading the technology section in Hydro projects, overseeing more than 170 employees, Ellen was assigned to the Sunndal Aluminium expansion project.

From 2002 to 2004, she commuted to Sunndalsøra four days a week, Monday to Thursday. The SU4 project meant a new prebake plant was phased in, with 340 cells based on Hydro’s own electrolysis technology. The investment totaled NOK 5.6 billion.

“It was a big transition. The methods in place for structuring aluminium projects were not as developed as the offshore projects. Therefore, we could now use a lot of our experience from the oil and gas years. Especially on specifications and completion in order to get more control of the project,” says Ellen.

“It was a great project. Very challenging, social and fun. The nature and surroundings are amazing. We went on a lot of hikes and enjoyed the nature to its fullest,” says Ellen, smiling as she looks back at the years in Sunndalsøra.

To celebrate the final construction steps of the SU4 project, the 20,000 square meter building turned into a concert hall with more than 1000 attendees.

Qatalum – the largest Norwegian industrial project abroad

Ellen was then asked to be the part of the Qatalum facility team in charge of developing the facility part of the Qatalum project. She was Project Manager for the facility part of the Qatalum project until DG3.

“It was massive and unlike anything we had ever done before. You need to have a lot of structure in place and split up the projects into several parts. The challenge is that the size itself becomes a challenge,” says Ellen, when asked what it was like to be part of such a huge project.

Hydro’s project organization managed the project, with a total investment of USD 5.7 billion. The first metal was produced on schedule in December 2009 and the plant reached full capacity in the fourth quarter of 2010, again according to plan.

This was the result of more than 90 million working hours. More than 56,000 workers from more than 200 companies were directly involved in the construction in Qatar.

Statoil bought Hydro oil and gas in 2007. With that transaction, more than 90 percent of the people in the project followed and left Hydro. Ellen and 61 other colleagues were left in Hydro projects, working to complete the Qatalum project. Ellen was appointed Vice President, Technical Management and Project Development.

“Of course I am happy! Just look at this star team which will run Hydro in the future,” said Hydro’s CEO at that time, Eivind Reiten, to Norwegian business newspaper Dagens Næringsliv. The title of the piece: “Running off with the A-team.” (in norwegian)

Building projects competence in Bauxite and Alumina

More than a hundred years after Hydro’s inception, the company became a full fledged aluminium company with activities throughout the entire value chain.

With its takeover of Vale’s aluminium activities in 2011, Hydro came full circle in Brazil. Ellen became the key to establish project competence in Hydro’s Brazilian branch.

“Me and my husband moved to Brazil in 2012. I travelled to Brazil with a somewhat diffused role. My task was to establish project competence in Bauxite and Alumina,” explains Ellen.

At first, Ellen worked on the Companhia de Alumina do Para (CAP) project, which was a potential construction of a new alumina refinery in Barcarena. The project was never realized, but Ellen continued to work on other key projects for Hydro.

Most importantly, Ellen was the Project Manager for the press filter and DRS2 Project in Hydro Alunorte.

Looking back, Ellen mentions this project as one of the most challenging projects of her lifetime. It was something completely new, in a new industry and new country, requiring a lot of work.

The press filter technology has been recognized for best practice sustainable bauxite residue management. The technology greatly reduces the area needed to deposit the bauxite residue generated from alumina and aluminium production.

Watch video to learn more about the press filter technology:

“Being able to structure the project unit around a concrete project was key. Then you can establish all the necessary systems around it. It is way better to use specific tasks to get everything in place, rather than to bring in a lot of procedures which do not make sense in practice,” explains Ellen, when asked how one builds a project organization from scratch.

Closing the loop with sustainable battery materials

In 2020, Hydro set out a forceful agenda towards 2025 of growing in low-carbon aluminium, and diversifying and growing in energy solutions.

“I have always believed that Hydro should be involved in more than aluminium. This gives so many more opportunities. And I guess this is also a reason for why I have stayed in Hydro for 40 years. In every new project you meet new people and challenges. It is like getting a new job every three years,” explains Ellen.

For the past few years, Ellen has worked on various batteries initiatives in Hydro. Among them, she has worked on ownership, project support and advice towards Vianode. Vianode is a sustainable battery material company owned by Elkem, Hydro and Altor, established on the back of electrification and the electric vehicle revolution.

In 2022, Vianode decided to invest NOK 2 billion in its first industrial scale plant for sustainable battery materials at Herøya in Norway.

Vianode’s range of anode graphite products offers unparalleled performance characteristics and is produced with 90 percent lower CO2 emissions than today's standard materials.

Reflecting on the role of sustainability in projects, Ellen explains that far more projects are driven by sustainability today.

“The press filter technology project in Alunorte was one of our first projects driven solely by sustainability ambitions. We used to think about sustainability, but now this has a lot more focus. Both from the organization and the market itself of course. This started to change more than ten years ago. Being part of a project aiming to produce battery materials in a more environmentally friendly way is exciting,” says Ellen.

But in reality, it is not a big change.

“Whether it is graphite production, renewables or aluminium recycling, a project is still a project. The structure needed to successfully advance a project is more or less the same. Building battery factories or new industries in 2023 is happening on the back of other large projects of the past. In many of these projects, there are people who started their career in oil and gas,” says Ellen.

Ellen’s colleagues in Hydro Projects are full of admiration of the legacy she is leaving behind.

“When I started in Hydro, I was star struck when Ellen presented her background. Now that she is retiring, we have a lot of her experience and knowledge embedded in Hydro’s more than 280 best practices and procedures. She is the person behind many of our best practices, and she is our go to person for clear answers and advise. She will be missed!” says Øyvind Lindhè Kjelsen, Head of Project Delivery in Hydro Projects.

Ellen’s takeaway: Grab the opportunities you get

Do you have any recommendations for the younger generation now embarking on a job in Hydro?

“The most important is to grab the opportunities you get. Say yes and be open to new challenges. This could entail commuting or increased travelling, and if you have a family this will depend on having a partner willing to take their turn. But rest assured, if you have kids they will survive. Everything will be alright,” says Ellen.

Is grabbing opportunities always easy?

“No, of course it can be challenging and complex. But I truly believe it is better to say yes than no. Looking back, you can say it did not work out or that you did not manage it. All of this is allowed in a company like Hydro. At least you tried,” says Ellen.

Ellen explains that her career path from petroleum technology to Sunndalsøra, Qatar, to Brazil and finally battery materials, with various line manager positions in between, was never planned. She never knew or planned for what the next step would be.

When reflecting on her role as a woman in a male dominated industry, Ellen explains that this has not necessarily bothered her.

“I was mostly the only woman in the room. But that was the reality. Thankfully, there are far more female engineers and technologists today than in the past. But still, the management teams are male dominated. In my view, this probably has a lot to do with the things we have talked about, flexibility, having young children and depending on a partner willing to take turns in career development,” explains Ellen.

What will you miss the most?

“The people I have worked with. And learning new things.”

And what do you plan to do now that you are retiring?

“I do not have any big plans. Maybe paint the cabin. Just things like that, at least in the beginning,” she says, smiling and looking into the window.

Ellen is planning to retire from Hydro in November 2023.