Light and maintenance free: This is why we should invest in aluminium in bridge constructions

Aluminium has been used in industry for years, and most of us are accustomed to seeing aluminium in various everyday products. But what many may not be aware of is that aluminium can advantageously replace other materials in bridge constructions.

Hydro is the leader in Norwegian aluminium production and is keen to promote the material's possibilities. Thomas B. Svendsen is an engineer with Hydro, and he talks about the potential of using aluminium in new areas. He says the possibilities are enormous, and that bridge construction is a field where it is time to consider new methods.

“Coming from a highly technical field, I often see a lack of knowledge about aluminium in some engineering circles as well as in regulations. For years, steel and concrete have been the dominant materials, because that is how it has always been done. There has been some innovation with regard to building bridges in wood or composites, and there have been some tests with aluminium, but not on a large scale,” he says.

“Our goal at Hydro is to shed light on the properties of aluminium for use in industry. We are in a unique position where we cover the full value chain from mining to semi-fabricated products. We are also a global leader in aluminium recycling.”

Industry needs to think in new ways

Svendsen talks about the obvious advantages of using more aluminium in larger, more comprehensive projects, including in transport infrastructure. Aluminium is strong and light, and therefore easy to handle. It is easy to shape and process. It has a long lifetime and requires very little maintenance. It is easy to recycle and can be reused endlessly.

These properties lend themselves well to bridge construction, he says, adding that a recent shift has sparked interest in new materials.

“There are other perspectives and arguments today,” says Svendsen. “These include the climate, environmental savings, value chains, more focus on sustainability. A new element that has entered the picture is emission reductions, in addition to costs.”

When it comes to bridges in particular, several projects are showing that aluminium indeed has a place. In 1995, Norway built its first aluminium bridge, the Forsmo bridge in Nordland. The bridge has held up well and is proof that aluminium bridges need only minimal maintenance. Similarly, the Arvida bridge in Canada, built in 1950, has passed several rounds of inspections. More bridges are now in development.

Mega-project with aluminium at the core

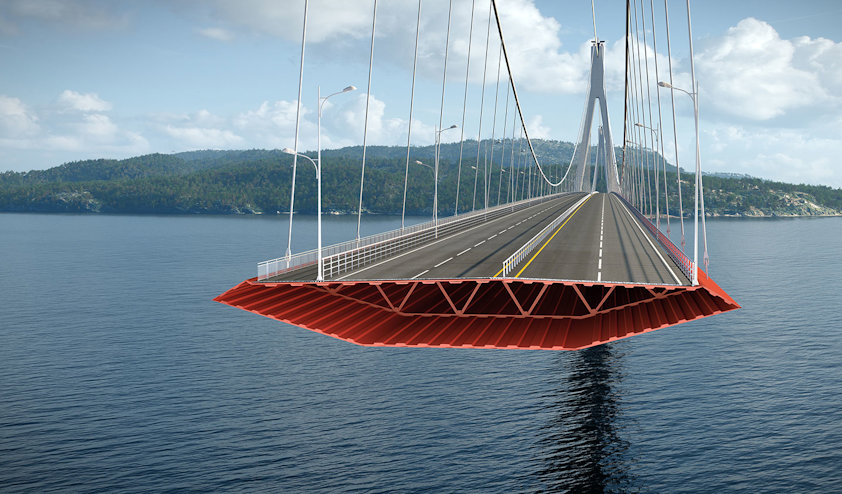

The Langenuen bridge might be the most exciting project under development. It is part of Norway’s ambitious Fergefri E39 project, designed to provide a smoother and more efficient travel route along the country’s west coast. The bridge over Langenuen Sound, south of Bergen, is to be built in aluminium.

“We have been working on this since 2016. The developer of the E39 project wanted to look at the entire cost picture, and whether technology from other industries could help. They wanted to look at materials, the supply chain and construction, and wanted to gain experience from, among other things, the oil industry. However, they had not considered aluminium,” says Svendsen.

“When we started the study, we first had to conclude that it was technically possible to build a bridge of this size with aluminium. We also considered the costs of using aluminium versus steel. Aluminium is normally more expensive than steel, but you get many synergy effects. As an example, the weight savings you get with aluminium can help reduce the use of concrete.”

He mentions other bridge projects in Norway that use aluminium, which are either complete or under planning.

“Grøndøla bridge is made of concrete, but aluminium is used as reinforcement instead of steel. This results in several positive effects,” he says. “For example, you use less concrete, you reduce maintenance costs over the lifetime of the bridge, and you get the benefits of recycling.”

The need for less concrete means that CO2 emissions are reduced. Concrete is the world's most-used building material, and accounts for 5-to-8 percent of the world's greenhouse gas emissions. The production of cement, which is the actual binder in concrete, accounts for 80-to-90 percent of the emissions from concrete.

An aluminium bridge will also require less maintenance. And after many years, when the bridge finally reaches its retirement age, the aluminum with which the bridge is built can be recycled and become a new bridge – or a car part.

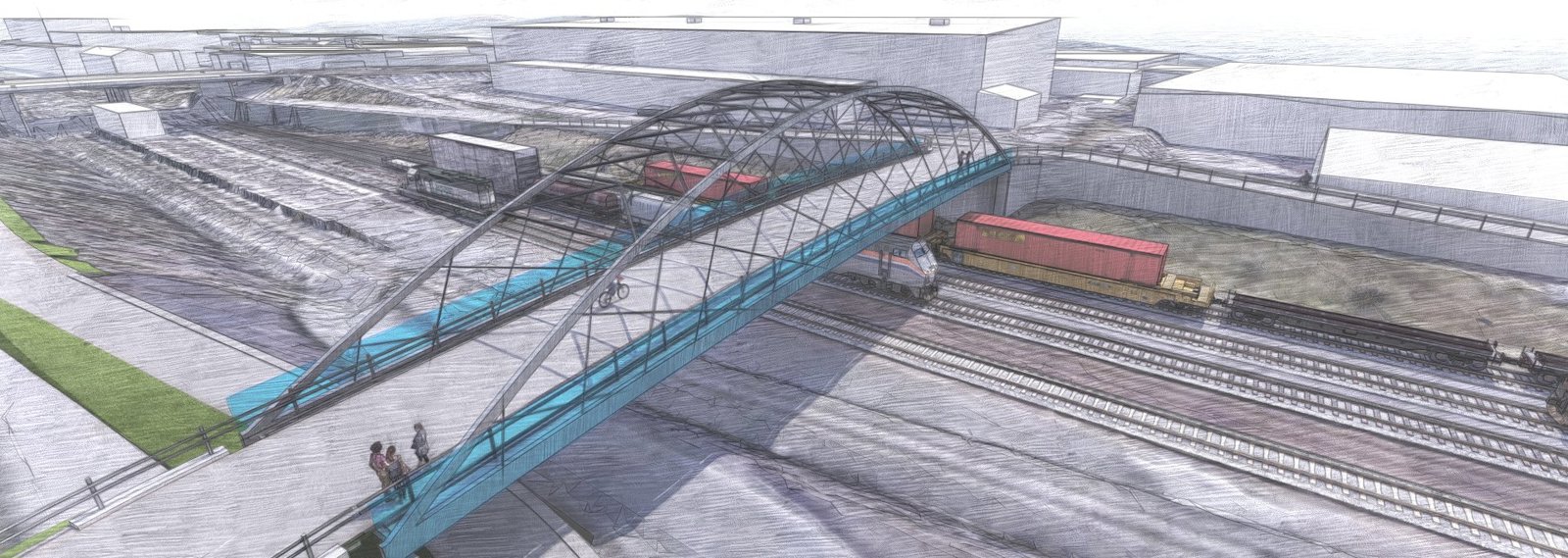

“Grøtta bridge is another that will be built in aluminium, and it will contribute to lower emissions and lower maintenance costs than the traditional alternatives,” says Svendsen, adding that the latest aluminium bridge project in Norway is the Hangarbroen in Trondheim. “This will carry pedestrians and cyclists over a railway line.

“The railroad is quite wide, with several tracks, so the bridge cannot be built too high, because it would mean too much of a slope for the bicycle path, nor too low, because then you would have a conflict with the trains. Using aluminium ensures that the bridge is lean and slim, yet still strong enough to withstand snow plowing, for instance.”

Bright future

Svendsen points out that these three bridges have unique challenges, and that these projects are providing Hydro with the opportunity to prove that it is physically possible to use aluminium for the bridges. And that this is just the beginning.

“We are getting inquiries from Canada and several countries in Europe, and we are talking to universities that show great interest in the projects. This could become a large market for us as a material supplier.

And it's not just bridges that can benefit from the good properties of aluminium. Svendsen lists offshore wind turbines, which today can struggle with stability and heavy constructions, as well as photovoltaic power systems and power plants as relevant industries.

“It is important to look at the whole picture. On the lifetime aspect,” he says. “Aluminium has properties that allow you to make big savings over the entire lifetime of a bridge. And a bridge can stand for 100 years. A master's thesis done at the Norwegian University of Science and Technology (NTNU) shows that the maintenance element of a traditional bridge often exceeds the construction costs.

“It is therefore important to increase knowledge about alternative materials. We would like to support the industry in this area.”