Unigrain profiles target a common form of waste

Peripheral coarse grain problems are a major cause of waste and increased costs for manufacturers who are using extruded aluminium profiles in 6082-type alloys in forging and machining.

The issue is that the outer layer of conventional forging stock and machining bar products often carries large crystals that can weaken the final product and lead to product failure.

Hydro’s unigrain technology presents a unique and affordable solution

Unigrain products are used in many sectors, including automotive and transport.

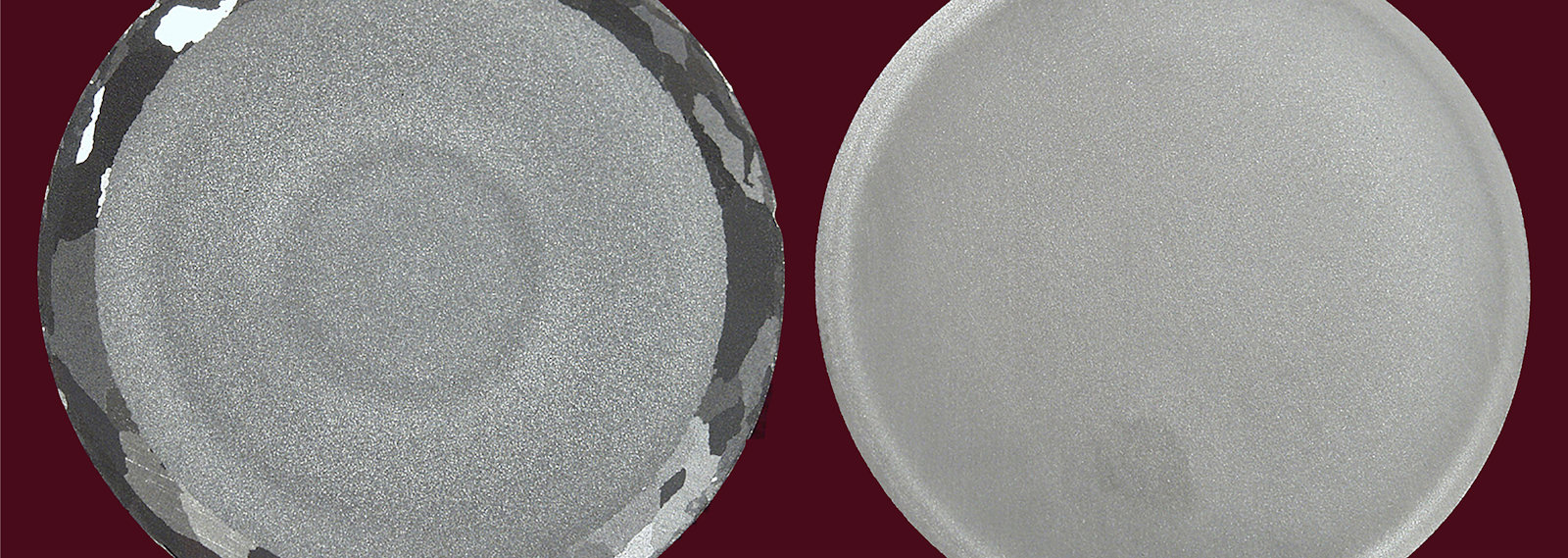

Regular profiles (pictured, above left) feature:

- Significant peripheral coarse grain problems. A thick layer of large-grained recrystallized microstructure on the surface leads to issues in further processing and inferior product quality.

- Limited geometric tolerance capability for profiles, due to an inferior extrusion process. Potential applications are limited.

- Significant levels of waste and increased cost, due to failure in the finished product.

Unigrain profiles (pictured, above right) feature:

- Peripheral coarse grain problems reduced by one order of magnitude.

- Geometric tolerances enhanced by one order of magnitude for relevant profile shapes, meaning more potential applications.

- Significant reduction in waste levels. Greater efficiency and lower cost.