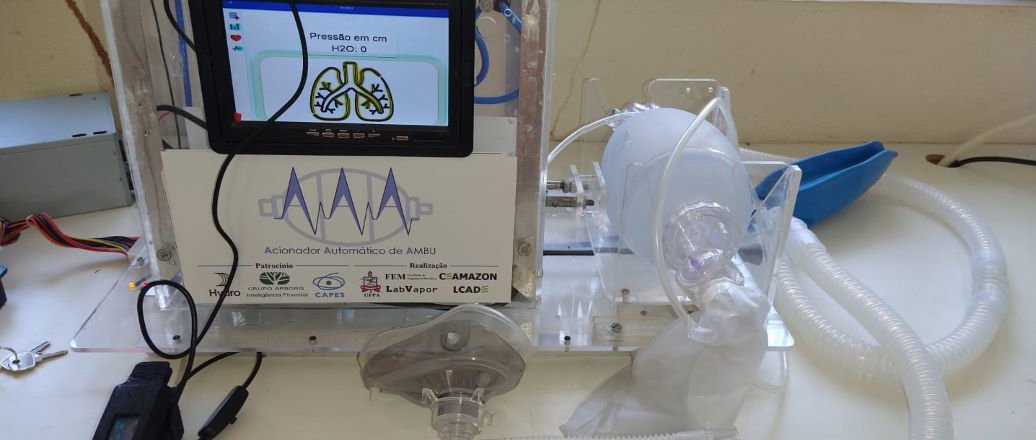

The Federal University of Pará (UFPA), in partnership with Hydro, is developing a prototype of an auxiliary device for respirators. The research began during the Covid-19 pandemic, as part of a technical-scientific agreement between the company and the university, and gained a new purpose after the decrease in the use of respirators with the advancement of vaccination. Now, the goal is to adapt the device to make it mobile and usable in ambulances and boats, especially in regions of the Amazon where access is only possible by river.

One of the main innovations of the prototype is its ability to work without electricity. The device uses an oxygen tank and compressed air to keep the respirator working, which makes it independent of external energy sources. The duration of operation depends on the storage capacity of the cylinder, which can be an efficient solution for areas with restricted power supply.

“The partnership between UFPA and Hydro has demonstrated the potential for innovation and the ability to face technological challenges to develop solutions that can have a positive impact on healthcare, especially in regions that are difficult to access, such as Amazon. The prototype of an auxiliary device for respirators represents a significant contribution to the fight against the Covid-19 pandemic and to the search for creative and accessible solutions in the health area. This project, as well as all others under the agreement with UFPA, is in line with Hydro's sustainability goals”, says Marcelo Montini, Hydro's senior chemical consultant.

The project had some challenges, such as the development of an automatic Ambu trigger prototype, used in intensive care units (ICUs), which is currently in the second phase of studies. In addition, the pneumatic system was maintained as a predominant approach, due to the need for electrical independence of the device, which can benefit energy-deficient cities. Another challenge was the development of a management system to treat and show the data collected by the sensors to managers.

“The equipment developed by the research helps in monitoring the vital parameters of patients with severe respiratory syndrome, such as the level of oxidation and heart rate, compensating for the supply of oxygen when necessary. This diagnosis is fundamental to select which patients really need mechanical respirators and who can have stabilized oxidation in the auxiliary device itself. The second stage of the project will allow portability in ambulances and boats, helping in the safe transport of patients from distant places”, explains the project coordinator and professor at UFPA, Marcelo de Oliveira.

One of the highlights of the project is the low production cost of the device, which uses easily found parts, such as the raspberry, and has an estimated cost of only R$ 3,000 in equipment and accessories. In addition, the production time is fast and the device can be assembled in a week, since all the necessary parts are available.

The project is also in the patent submission process and has yielded results, such as the publication of an international article and a master's thesis. The prototype is already working and the next steps include the development of a 2.0 version, focusing on aspects such as noise, transport in traffic, battery system and adaptation to a portable system, in order to be used on boats and interruptions.

: June 26, 2023