Aluminiums formbarhed

Formbarhed er en af de stærkeste egenskaber ved det lette metal aluminium.

Vores forsknings- og udviklingsingeniører benytter moderne udstyr til at udføre computeranalyser og tests af sektioner formet ved hjælp af varmgasformning, hydroformning, strækformning og bukning. Det gør vi, fordi du gerne vil kunne skabe komplekse dele med en høj grad af dimensionsnøjagtighed.

Yderligere maskinbearbejdning

Profiler kan formes, så de kun kræver minimal maskinbearbejdning efter ekstrudering. Men visse former for behandling er ofte nødvendige, og maskinbearbejdning af profiler er relativt billig. Aluminiums formbarhed betyder, at værktøjsomkostningerne er konkurrencedygtige.

Hydroformning og bukning sikrer nøjagtighed

Ved hjælp af hydroformning kan vi forvandle et ekstruderet aluminiumrør til en tredimensionel form. Bukning er en anden proces, som vi bruger for at opnå nøjagtig formgivning.

|

Lacquering  |

This process allows your profiles or aluminum parts to be lacquered with a wide variety of colors while guaranteeing exceptional performance against UV, corrosion, impact and abrasion. |

Anodizing  |

This treatment by electrolysis specific to aluminum provides a finish that is pleasant to the touch and durable in the face of external aggressions. It is possible to obtain shades of tints in particular by virtue of the spectrocoloration process. |

|

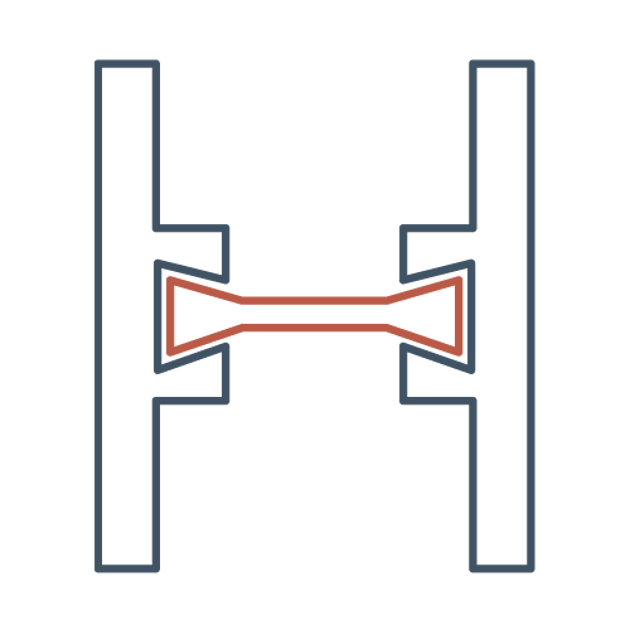

Crimping / Barrettage  |

By associating polyamide bars with aluminum profiles, crimping or barrettage makes it possible to obtain a complex with a thermal break. This operation can be used to link an aluminum profile with other materials. |

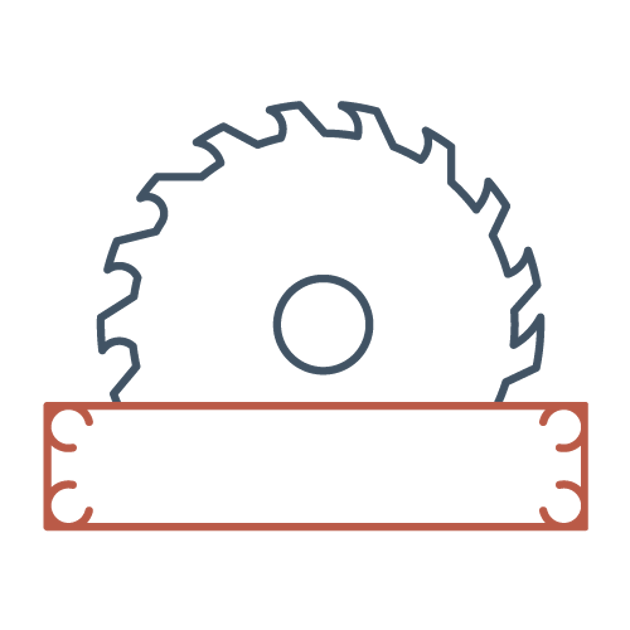

Cut to length  |

Thanks to our different cutting means, it is possible to re-cut the profiles to make pieces from 5mm to 12m long. |

|

Machining  |

Our machine park makes it possible to machine from the small part for the automobile to the large part of several meters for the building and industry. With our 5-axis machining centers, it is possible to multiply the functions of your profile. |

Punching  |

By developing specific tools, this process makes it possible to carry out shearing and cutting operations very quickly and therefore inexpensively for large series. |

|

TIG / MIG welding  |

6000 series aluminum alloys weld very well via the TIG or MIG process. In addition, the aluminum extrusion makes it possible to integrate functions that facilitate welding. |

FSW welding  |

This weld obtained by mixing the material with a rotating tool has many advantages: reduced deformation, homogeneous weld, flush weld, excellent thermal conductivity, etc. |

|

Bending  |

Depending on the type of bent desired, the section of the profile, the quantities, different alternatives exist: bending by stretching, bending between rollers, bending in a press or bending by traction. |

Mounting  |

From the installation of gaskets to the crimping of threaded inserts, a complete solution can be offered to deliver a finished product. |

|

Kitting  |

Through the various workshops, the kit of your product can be carried out according to your specifications such as specific wedging, protection by filming, installation of stickers, integration of bags of screws , etc. |

Storage  |

As part of your activity, your profiles can be stored under certain conditions in order to put them in stock according to your supply criteria on a logistics basis. |

|

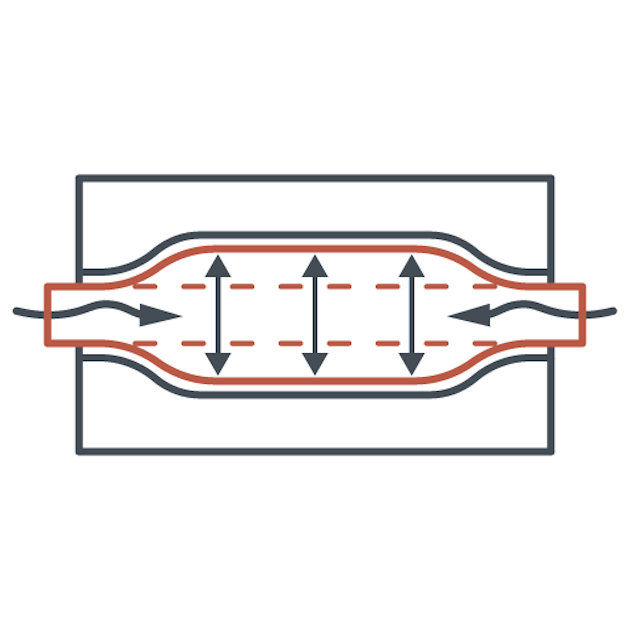

Hydroforming  |

With hydroforming, we can turn an extruded aluminium tube into a three-dimensional shape. |

|

|