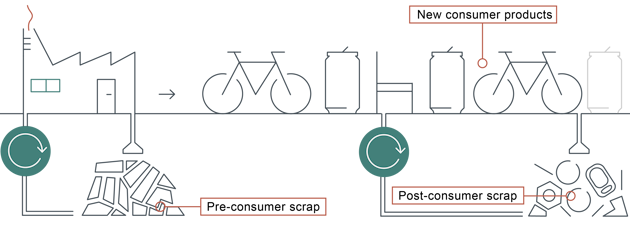

The key to a circular economy is planning for a product’s life cycle already at the drawing board, designing products in recyclable materials that last longer and that can be taken apart and recycled when no longer in use.

To show you, we decided to make a chair, with sustainability as the design brief.

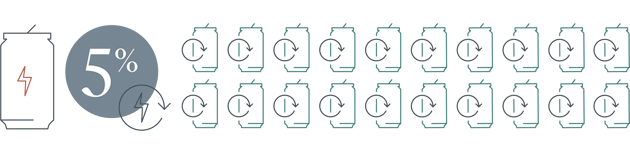

Aluminium is a 100% recyclable material, and producing recycled aluminium requires only 5% of the energy required to produce primary aluminium.

Therefore, we need to make sure all our post-consumer aluminium scrap can go back into the loop again and again.

Post-consumer aluminium scrap is like an unlimited energy bank and plays a vital part in the future of the circular economy.

Pre-consumer scrap is typically scrap that comes from the production process and has never been used before it is remelted again.

Post-consumer scrap is aluminium that has already lived a “life” – maybe in a window frame or a can – and has now been recycled to be turned into something new. The most CO2-efficient recycled aluminium products are the ones made from post-consumer scrap.

Updated: 11 November 2022