Aluminum has a life cycle that few other metals can match. It is corrosion resistant and can be recycled over and over again, requiring just a fraction of the energy used to produce the primary metal.

This makes aluminum an excellent building material - reshaped and repurposed to meet the needs and challenges of different times and products.

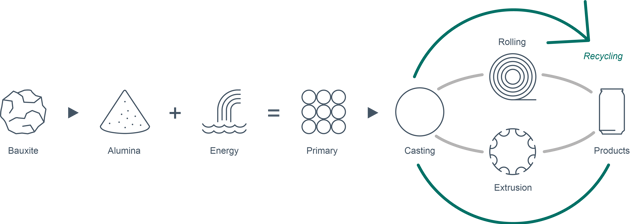

How it’s made

1. Bauxite mining

Aluminum production starts with the raw material bauxite, which contains 15-25 percent aluminum and is mostly found in a belt around the equator. There are around 29 billion tonnes of known reserves of bauxite and at the current rate of extraction, these reserves will last us more than 100 years. There are, however, vast undiscovered resources that may extend the time perspective to 250-340 years.

2. Alumina refining

Using the Bayer process, alumina (aluminum oxide) is extracted from bauxite in a refinery. The alumina is then used to produce the primary metal at a ratio of 2:1 (2 tonnes of alumina = 1 tonne of aluminum).

3. Primary production

The aluminum atom in alumina is bonded to oxygen and needs to be broken by electrolysis to produce aluminum metal. This is done in large production lines and is an energy-intensive process, requiring a lot of electricity. Using renewable power and continuously improving our production methods, is an important means to meet our goal of being carbon neutral in a lifecycle perspective by 2050.

4. Fabrication

Hydro supplies the market with over 3 million tonnes of casthouse products annually, making us a leading supplier of extrusion ingot, sheet ingot, foundry alloys and high-purity aluminum with a global presence. The most common uses of primary aluminum are extruding, rolling and casting:

Extruding

Extrusion allows for shaping aluminum into almost any form imaginable using ready-made or tailored profiles.

Rolling

The aluminum foil you use in your kitchen is a good example of a rolled aluminum product. Given its extreme malleability, aluminum can be rolled from 60 cm to 2 mm and further processed into foil as thin as 0.006 mm and still be completely impermeable to light, aroma and taste.

Casting

Creating an alloy with another metal changes the properties of aluminum, adding strength, brilliance and/or ductility. Our casthouse products, such as extrusion ingots, sheet ingots, foundry alloys, wire rods and high purity aluminum, are used in automotive, transport, buildings, heat transfer, electronics and aviation.

5. Recycling

Recycling aluminum takes only 5% of the energy required for producing the primary metal. Also, aluminum doesn’t deteriorate from recycling and 75 percent of all aluminum ever produced is still in use. Our goal is to grow faster than the market in recycling and take a leading position also in the recycling part of the aluminum value chain, recovering 1 million tonnes of contaminated and post-consumer scrap aluminum annually by 2020.

Updated: May 15, 2024