Keeping materials in the loop

In a more unpredictable world with disrupted global supply chains we need access to safe and reliable streams of raw materials. Keeping the materials, products, or services we produce in circulation for as long as possible makes our value chains more resilient and reduces waste. In addition, we need more reliable and transparent information about where products come from and how they are produced. When materials or products eventually reach their end-of-life and have been put to good use, we need to ensure they are recycled and turned into new products.

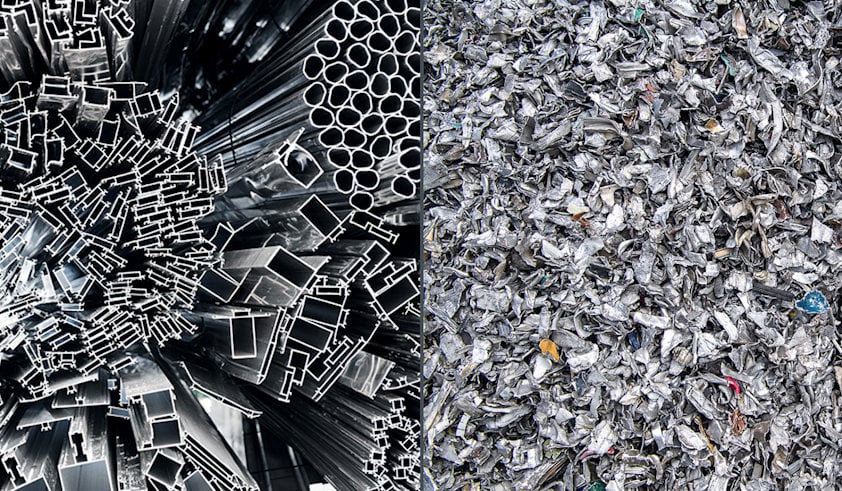

In theory, most things can be recycled, but some materials are better suited for recycling than others.

Aluminum is infinitely recyclable and retains all its qualities no matter how many times it’s recycled. This is why it’s called a permanent material. Moreover, when you recycle aluminum, you use 95% less energy than when producing aluminum the first time. This makes it an ideal metal for the circular and low-carbon economy.

However, not all recycled aluminum is equal.

Understand the carbon footprint of your aluminium

Consumers see that they can play a big part in the green transition by buying more sustainable products and ask for more transparency about how the products they buy are made, and where the materials come from. Therefore, the market for greener and more sustainable products is growing.

Many environmentally aware companies want to lower the carbon footprint by increasing the amount of recycled materials in their products.

To truly understand the carbon footprint of your recycled aluminum, you need to know the kind and amount of scrap used in the recycling process. The ISO 14021 standard defines recycled content being made with post-consumer scrap and pre-consumer scrap.

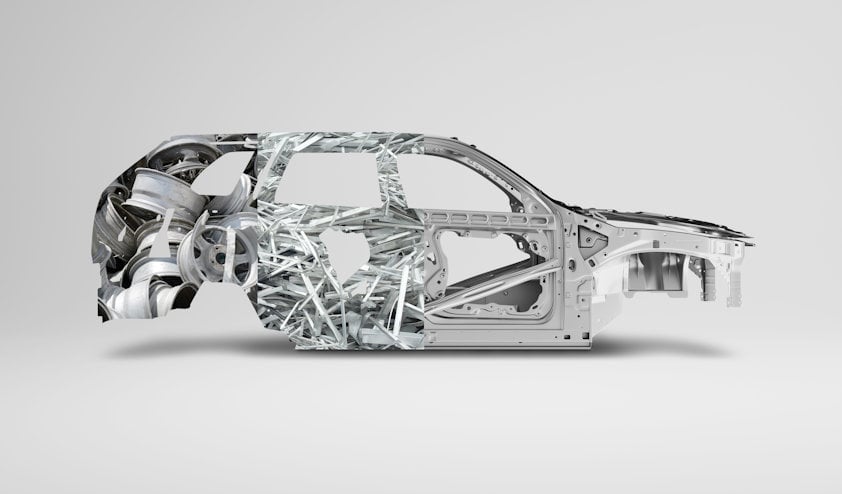

When recycled aluminum is made from used windows or car parts, the material starts another life. Previously used aluminum in a product is referred to as “post-consumer” scrap, and its carbon footprint has already been accounted for, and is therefore close to zero. Recycled aluminum made from production scrap or “pre-consumer” scrap is different.

It is a result of inefficiency in the manufacturing process, it has not yet completed its life and must retain the carbon footprint of its original production process. If this isn’t done, there is a high risk that the material’s production emissions are not accounted for.

Transparency is key

In Hydro, we believe our customers should know the actual footprint of recycled aluminum, not just the percentage of recycled content. This is the only way to support the circular transition.

Overstating the environmental facts or label products as “green” or “sustainable” when the full CO2 footprint is not included is greenwashing. It is also important to keep in mind the distinction between post-consumer and pre-consumer scrap.

Hydro have created certified low-carbon and recycled aluminum offerings, minimizing the carbon footprint of our products while ensuring safe and responsible production. We are also currently testing a blockchain pilot for tracing our products’ journeys throughout the value chain and their life cycle. This fosters circularity, transparently showing the carbon footprint and recycled content of our aluminum.

Material selection and the importance of design for recycling

Knowing that aluminum is a material that is infinitely recyclable – without loss in quality – it makes sense to design aluminum products in ways so it can be easily disassembled and recycled again.

Up to 80% of a product's environmental footprint is decided in the design phase. It goes without saying that engineers and product designers - through their material and design choices - have great influence on a product’s sustainability. A good starting point is the material choice, and ensure that the product can be recycled, in accordance with new requirements that are on the way from regulators.

By starting with material selection early in the design phase, customers can help develop goods produced with fewer resources, which last a long time and can be recycled. With Hydro EcoDesign, products get increased functionality and smaller environmental footprints.

When engineers and designers familiarize themselves with the principles of Eco design, they can help accelerate the green shift and ensure that consumers have greater freedom of choice on more-sustainable products. Read more about how EcoDesign can reduce the environmental footprint.

Innovation through partnerships

To decarbonize the biggest industries in the world and lead the way towards a net-zero society, Hydro partners with forward-leaning customers to lower the carbon footprint of their products.

The recycling of post-consumer scrap is the fastest way to deliver aluminum with a CO2-footprint of zero in industrial-scale production by 2030. In April 2022, we managed to produce the first batch of close to zero emission aluminum.

This only possible due to our state-of-the-art recycling technology, which includes sorting, shredding, and melting technologies. Our technology enables us to recycle more challenging types of post-consumer scraps.

We have also developed an advanced laser induced breakdown spectroscopy, allowing us to dig deeper into the scrap pile and recycle more challenging scrap types. This is scrap that historically might have gone into secondary castings or even left the loop altogether, ending up in landfills.

Our technology enables us to produce near-zero aluminum, defined as aluminum with a footprint of 0.5-1 kg CO2e /kg aluminum, throughout the value chain.

To reduce the product footprint to zero, Hydro’s target is to develop technology to replace natural gas with renewable energy in the form of electricity, biogas, or green hydrogen for the casthouse furnaces. This requires further research and development, where our green hydrogen company Hydro Havrand is coordinating a study to look at alternatives.

Hydro’s technology roadmap aims to shape a credible pathway towards near zero products today, and zero products in the future. By decarbonizing our aluminum products, we help customers reach their sustainability goals and meet the demand from ever more climate-conscious consumers. Read more about our technology roadmap to zero.

Hydro’s recycling operations

Hydro’s recycling operations consist of 26 recyclers in Europe, United States and Canada for our Aluminum Metal and Extrusions business areas. We also have a sorting facility in Dormagen, Germany. We’ll be at 27 in total when the greenfield project in Szekesfehervar, Hungary is finished. The total capacity is approximately around 2 million metric tonnes per year.

Updated: May 15, 2024