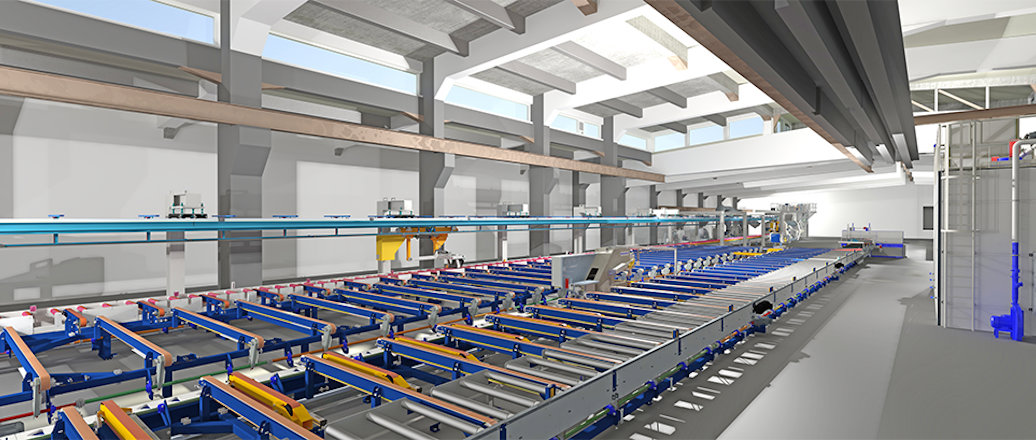

The foundation work in the hall has now been successfully completed, which represents an important milestone. The assembly of the press line can now begin, which means that the overall picture of the new system is slowly taking shape. To ensure on-time completion, a heavy-duty transport is planned for early August, which will deliver press components for integration into the facility.

In addition to the construction of the extrusion press, the tool technology area will also be renewed. Construction work has also started here and the focus is not only on enlarging, but also on modernizing and optimizing the ergonomic conditions in the workplace. Employees will benefit from these advances as the improved work environment translates into increased efficiency and comfort. The precise coordination of the tool technology with the new extrusion press will create a synergy that ensures smooth production and the highest quality standards.

We also pay particular attention to sustainability and energy efficiency. As part of the plant expansion, an innovative recooling system was installed that represents a resource-saving solution. The new installation will make a significant contribution to reducing water consumption and electrical energy. With this eco-friendly approach, the company becomes a pioneer in sustainability, which not only takes environmental responsibility, but also generates cost savings.

In summary, it can be said that the progress made with the new aluminum extrusion press at Hydro Extrusion Rackwitz is impressive and with each completed stage the company is one step closer to its goal of efficient production. Investing in future-oriented technology and sustainability will give Hydro Extrusion Rackwitz a strong position in the aluminum processing industry.

: 21 August 2023