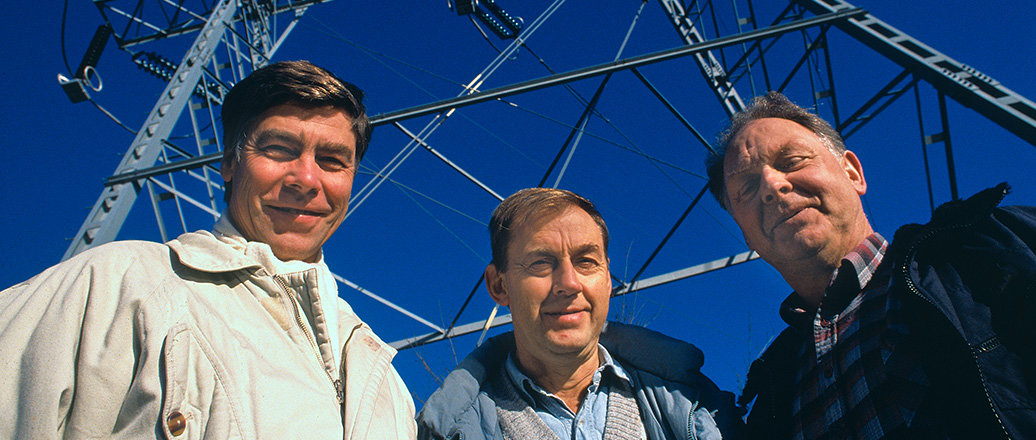

“We stood watching the lines swing back and forth in the wind,” says Per Seglem. Together with his colleagues at the Røldal-Suldal power plant (RSK), he found himself at the centre of a dramatic episode. So was the director of the power plant Arild Syvertsen.

Unable to withstand the force of the storm, the pylons toppled over. The result was disastrous, not least for aluminum production at Alnor, as the plant was called then.

The men at RSK saw what had happened straight away. Great steel profiles lay twisted like a pile of scrap metal. High voltage lines lay across the sound, almost in the water, and were blocking the shipping route.

Going out of doors in the factory area was in itself dangerous with debris being swept through the air.

Keeping warm

Inside the plant, the electrolysis cells were covered with oxide to try to keep in the heat, but it wasn’t possible to prevent the aluminum from stiffening. They also tried lowering the anodes closer to the surface of the electrolytic bath, and this didn’t help either.

The atmosphere in factory manager Erling Knutsen’s office was rather sardonic. By the light of a candle everyone was intensely trying to work out how to keep the baths at a level that would allow operations to start up again once the electricity was re-connected.

A provisional electricity supply was set up after four and a half days, but a good deal of hard work remained for Hydro’s workers in the potrooms at Karmøy, the local electricity company and the employees at the Røldal-Suldal power plant.

Hard work

The work to set up a provisional supply continued night and day, often in the pitch dark as the whole district was without electricity. It was all rather surreal, especially when large flakes of snow started to fall.

Then large quantities of ice started to build up on the electricity lines to Røldal. This caused major problems: nearly 30 kilos per meter was beyond the design specifications of the high voltage masts.

Meanwhile on the mainland, a series of challenges were waiting for the attention of people like Seglem and Nils Brekke. During part of the repair operations, Seglem was tied into a basket and raised up to connect the power lines while being was blasted by the wind from behind.

This took several hours, but when the message was received that several other masts were down, they decided it would not be a good idea to turn on the voltage.

At one point, nearly 50 men from RSK were at work on clearing away broken masts, putting up provisional masts and straightening those that were hanging over.

Useful lesson

The company had drawn up emergency plans for the masts across the sea, but these provided for the possibility of an aircraft accident not a storm.

The great storm proved to be a useful lesson. New calculations were made with the conclusion that the power lines were not strong enough. Since then RSK has carried out continual work on strengthening the high voltage masts.

Reconnected

It was the operations centre at Nesflaten that coordinated the work to set up a provisional connection with the Karmøy factories. But there was little they could do until people like Seglem and Brekke fixed the necessary connections.

When the electricity was finally back again, there were, therefore, a number of people who heaved a great sigh of relief.

Updated: August 18, 2020