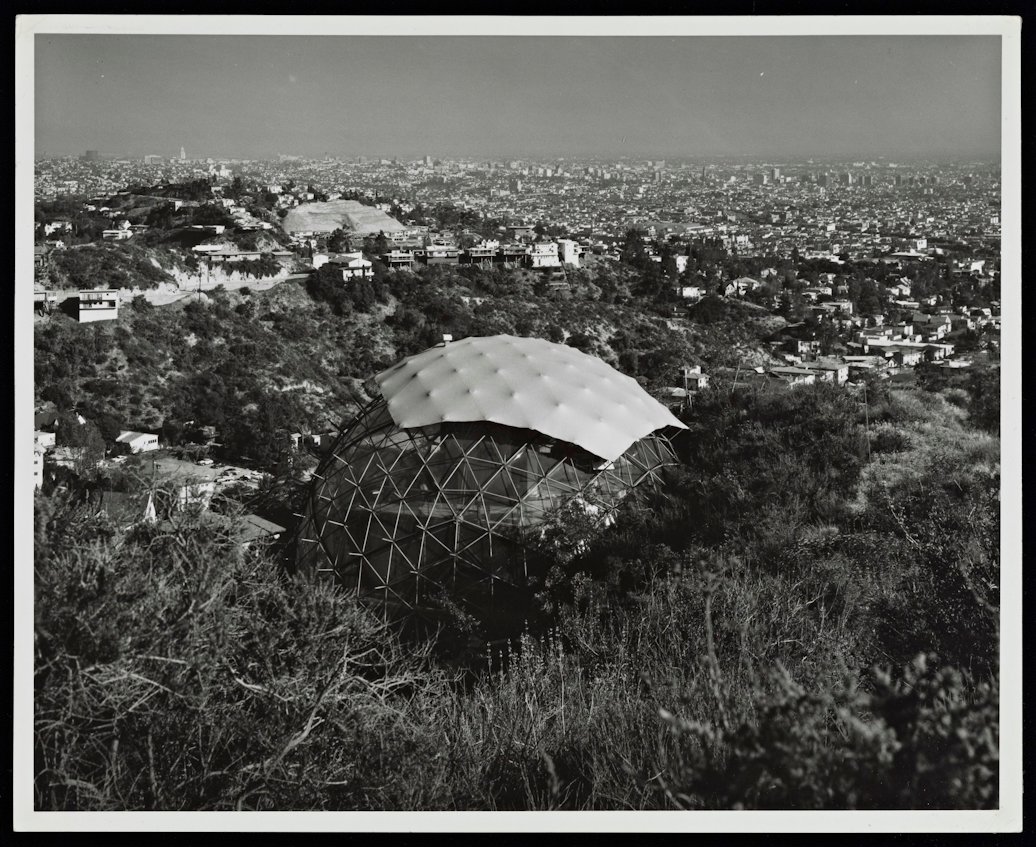

The dome, known as Weatherbreak 8C270, is the world’s first large span, self supporting geodesic dome, originally constructed on the outskirts of Montreal, Quebec, in 1950. Utilizing the theories of renowned American architect, inventor, and futurist Buckminster Fuller, Jeffrey Lindsay, a former student of Fuller’s and director of the Fuller Research Foundation’s Canadian Division, designed the innovative 8-frequency hemispherical icosahedron and oversaw all aspects of its manufacturing, and installation.

Much like the aluminium from which it is made, Lindsay and Fuller envisioned Weatherbreak as an elegant and futuristic solution to many of the challenges of their era. The unique properties of aluminium enable the structural design to be lightweight, strong, and highly efficient. The dome, now part of the museum’s collections, originally consisted of nearly 1,000 pieces, many of which were damaged or lost over the course of time. Hydro is helping to replace these missing pieces by providing extruded aluminium made with Hydro CIRCAL, which offers the lowest carbon footprint of any aluminium products manufactured in the world today.

The student led reconstruction of Weatherbreak at the Smithsonian’s National Museum of American History will begin in early July and will remain on exhibit through the end of the month. Museumgoers will be able to watch the progress in real time and once built, be able to walk through the dome as part of "Reconstructing 'Weatherbreak': Geodesic Domes in an Age of Extreme Weather.”

“Thanks to Hydro, we can participate in the restoration of a truly historic piece of architectural history. This project is a great learning experience for our students and the use of varied materials is an integrated part of their architecture education. We are looking forward to learning more about the benefits of aluminium as a sustainable building material through the partnership with Norsk Hydro,” says Tonya Ohnstad, Associate Dean of Graduate Studies, Assistant Professor at Catholic University’s School of Architecture and Planning.

Architects have long been advocates for the use of sustainable materials and lifecycle thinking, so it is no surprise that aluminium plays a significant role in the modern built environment. Just as the student led project seeks to conserve a unique piece of architectural history, recycling aluminium conserves resources and energy. Unique among modern building materials, aluminium is also infinitely recyclable, so it naturally makes sense to design aluminium products in ways that are easy to disassemble and reclaim at the end of their useful life.

“Hydro is pleased to partner with Catholic University to assist the Smithsonian in helping revive this historic structure. Much like Fuller’s vision for “Spaceship Earth,” for nearly 120 years Hydro has sought to create a more viable society by developing natural resources into products and solutions in innovative and efficient ways,” stated Trond Gjellesvik, President of Hydro Aluminium Metals USA. “The team at our Henderson, Kentucky, recycling plant was able to produce extrusion ingots for this historic project almost entirely from post-consumer scrap, the reuse of which is critical to improve sustainability.”

Hydro formed this recycled material into the extruded profiles used in the structure at its extrusion facility in Elkhart, Indiana, one of the company’s many manufacturing sites in North America supplying the building and construction industry. “By increasing the use of post-consumer scrap and driving towards 100% recycled content, aluminium can play a vital role in decarbonizing the building industry” noted Charlie Straface, President of Hydro Extrusion North America. “By taking end-of-life aluminium scrap and transforming it back into building components, we feel this project highlights the potential of aluminium to address climate change in unique ways.”

In addition to providing replacement pieces for the original structure, Hydro is providing enough material for Catholic University to construct a replica dome for a traveling exhibit in the future. Should that structure ever reach the end of its useful life, it will have an infinite future ahead of it.

Published: May 4, 2023